From Dust to Divine: The Quiet Magic of Marble Dust Statues

I’ll never forget the first time I walked into a master sculptor’s workshop. The air was thick with a sweet, earthy smell of clay and the faint, rhythmic sound of sanding. But what caught my eye wasn’t a giant block of marble—it was the bins of fine, white powder tucked away on a shelf, glowing softly in the afternoon light.

“That’s the secret,” the sculptor told me with a wink, dusting his hands on his apron. “That’s where it all begins. Not with a bang, but with a whisper.”

That whisper is marble dust. And in the hands of a skilled artist, this humble material undergoes a kind of quiet magic, transforming from what looks like simple powder into statues of gods and goddesses that feel alive with serenity and power.

This craft is a beautiful bridge between the ancient and the everyday. It makes the sublime accessible, turning the very essence of the mountain into something we can connect with in our homes and hearts.

So, What Is This "Magic Powder" Anyway?

Let’s demystify this. Marble dust isn’t some complex, man-made chemical. It’s quite literally the mountain, remembered.

Imagine a marble quarry. Huge, majestic blocks are cut from the earth. As they’re shaped and polished for countertops or grand sculptures, they release a fine, crystalline powder. Instead of seeing this as waste, artisans see it as potential. This powder is collected, sifted until it’s as fine as confectioner’s sugar, and given a second life.

It carries the soul of the original stone—the same coolness to the touch, the same potential for brilliance, the same luminous white. Using marble dust is an act of respect. It’s a way of saying, “We will use every part of your gift.” It’s sustainable, it’s practical, and it’s deeply poetic.

The Journey: How a Pile of Dust Becomes a Deity

The foundation of the statue is the material itself. It is not a solid block of marble, but a composite that uses genuine marble as its main component.

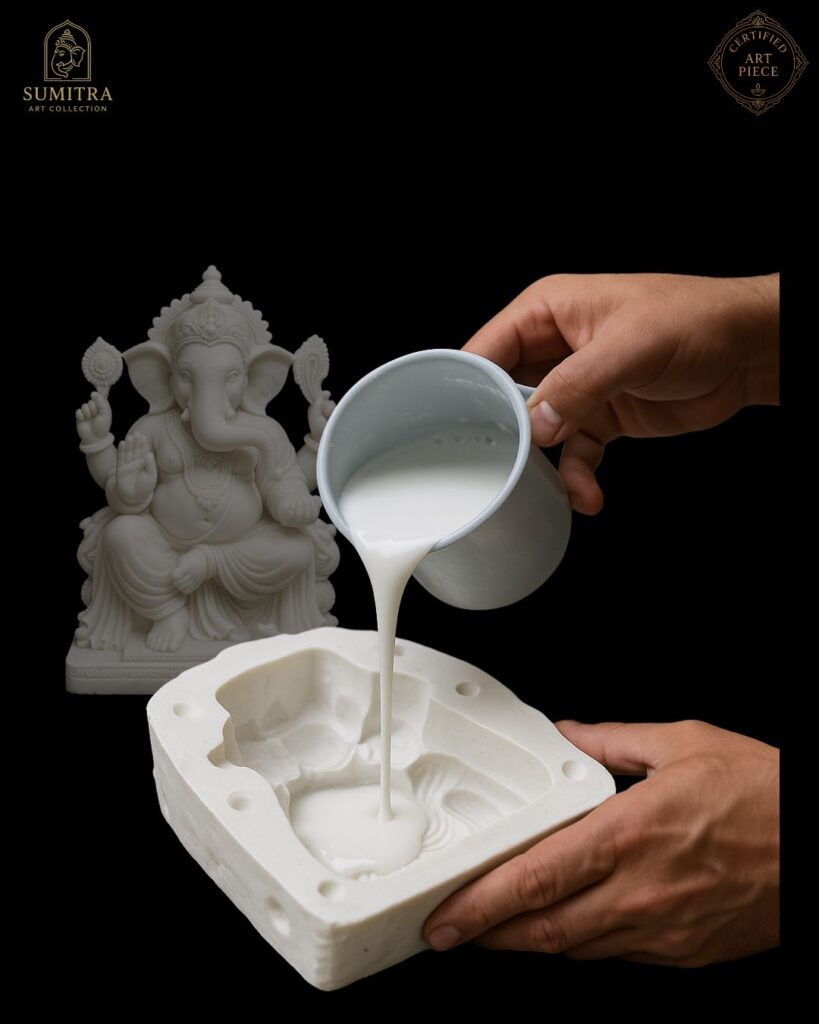

“Statues are made by mixing marble dust with a bonding agent, creating a mold, baking the piece, and then sanding and polishing.” [2]

- Marble Dust: This is the fine powder, or “dust,” created as a byproduct when carving and shaping natural marble. It is the core ingredient, giving the final product its characteristic weight, texture, and cold touch.

- Bonding Agent (Resin): The marble dust is mixed with a high-quality, durable synthetic resin (often polyester or epoxy resin). This resin acts as the “glue,” binding the marble particles together into a solid, workable compound. The ratio is crucial, ensuring the final product is strong yet retains the aesthetic qualities of stone.

Casting: The Art of the Mold

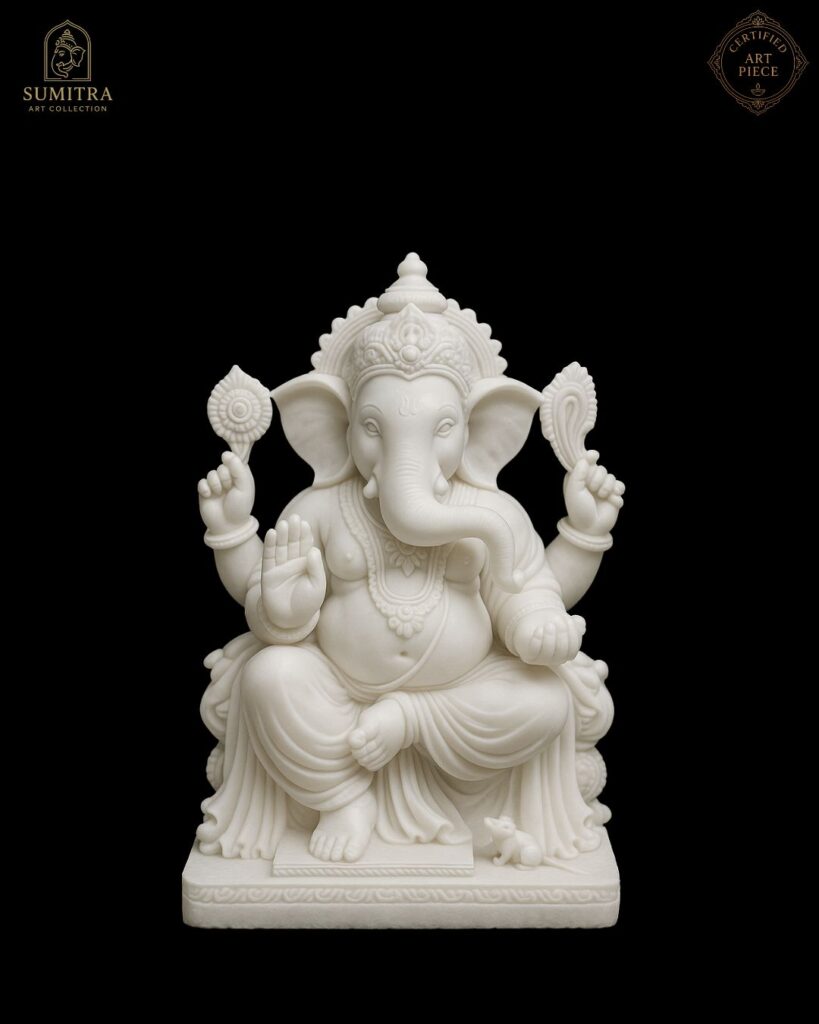

Curing: Solidification and Strength

Finishing: The Touch of the Master Artisan